The hyper i control utilizes a straightforward 3 step operation process of program setup run and this efficient and user friendly interface is used for all makino wire and ram edm machines.

Makino wire edm programming.

The machine utilizes a stationary work table design that delivers repeatable accuracy regardless of work piece size or weight.

He machine is built on the proven makino uj series wire edm platform that utilizes a stationary table design and is held to an even higher construction accuracy specification.

As part of the makino upj 2 the world s only conventional horizontal wire edm machine wirewizard technology delivers higher speed and better surface finishes with fewer passes and superior accuracy with substantially reduced consumable and maintenance costs.

Programming operation control technology the conditions for efficient production are mainly determined by selection of the appropriate production equipment.

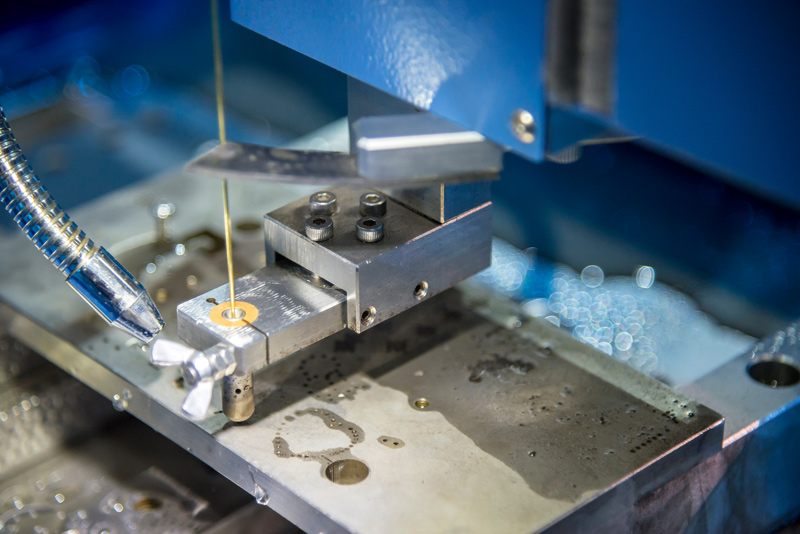

The upv 3 wire edm machine was designed to produce the ultimate in precision machining while achieving ultra fine surface finishes.

Makino is the world leader in wire edm giving you faster processing times and superior surface finishes for even the most complex part geometries.

The makino u3 wire edm provides an ideal mix of speed accuracy and surface finish capability to tackle the most demanding applications.

The large 24 class hd touch screen display provides a commanding view for the operator and utilizes intuitive and familiar touch pinch swipe drag operations similar to smartphones and tablets.

The hyper i control is also standard with digital onboard electronic manuals instructional training videos and advanced e tech doctor help functions that.

Half the maintenance half the wire most edm machines chew through more than one pound of wire per hour making wire consumption the biggest expense of operating wire edms.

But efficient use of that equipment is dependent to a high degree on how professionally trained the operators are.

With pinpoint sub micron precision and outstanding surface finish these oil based dielectric horizontal wire edms are ideal for small electronics medical and micromachining applications.

Makino offers a range of wire edm machining solutions.

Makino edm exclusive that gives you industry leading control technology.

The large 24 class hd touch screen display provides a commanding view for the operator and utilizes intuitive and familiar touch pinch swipe drag operations similar to smartphones and.